Precision Machining

Precision Machining Solutions for Critical Applications

MIC Group delivers world-class precision machined components, serving a diverse range of industries that demand exceptional quality, reliability, and performance. Our state-of-the-art manufacturing facility is equipped with the latest advancements in CNC milling, turning, gundrilling, and EDM technology, allowing us to produce high-precision, close-tolerance components from both standard and exotic materials.

Our vertically integrated approach streamlines every stage of the manufacturing process, from material sourcing and machining to final inspection and assembly, ensuring superior quality control and optimized lead times. By leveraging cutting-edge automation, multi-axis machining, and advanced programming, we enhance efficiency, repeatability, and cost-effectiveness—even for the most complex, high-specification parts.

At MIC Group, we don’t just manufacture components; we engineer manufacturing solutions that meet the most demanding industry standards. Whether you need prototype development, low-volume precision machining, or high-volume production, our expertise in precision manufacturing and process optimization ensures on-time delivery and consistent quality—every time.

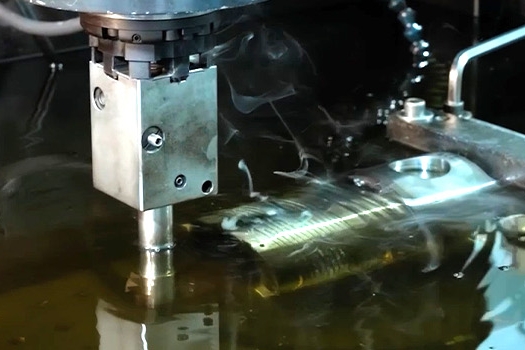

Gundrilling is a special and unique machining service that creates a long, very straight, relatively small diameter hole. Typically, this specialized service is not a core competency of a machining organization.

MIC Group is pleased to offer in-house gundrilling to our customers to eliminate the extended project lead time associated with outsourcing. This, in turn, saves our customers time and money.

Gundrilling Key Features:

- Applicable to a broad range of materials.

- Very accurate at high tolerances.

- Easily repeatable

- Smooth surface finishes

- Eliminates need for deburring, reaming and work hardening.

Gundrilling Specifications

| Min Diameter & Max Depth | .093″ x 30″ |

| Min Diameter & Max Depth | 1.5″ x 72″ |

Our extensive experience with milling is a true competitive advantage. Whether your needs require a vertical or horizontal mill, our knowledge and industry leading equipment enable us to tackle the most difficult of our customers’ milling requirements.

- 5-Axis vertical mill capabilities

- Horizontal boring mills

Milling Specifications

| Vertical | Horizontal | |

| Type | CNC | CNC |

| Through Spindle Coolant | Yes | Yes |

| High Pressure Coolant | Yes | Yes |

| Dual Pallet | No | Yes |

| # of Axis | 5 X,Y,Z | 4 X,Y,Z |

| Working Envelopes/Max | 120” x 35” x 40” 120” x 40” x 30” 141” x 36” x 32” | 59” x 47” x 27” 60” x 60” x 48” 118” x 90” x 63” |

| Vertical | Horizontal | |

| Types | CNC, Manual | CNC |

| Spindle Bore Size | 1″ to 10 1/2″ in diameter | |

| # of Axis | 2 | 2 |

| Live Tooling | Yes | |

| Max Swing | 8” to 40” in diameter | 98″ |

| Max Turning | 6” to 32” in diameter | |

| Min Workpiece OD | 1/16” to 5” in diameter | |

| Max Boring Depth | 3” to 40” in length | |

| Distance between Centers | 12” to 224” in length | |

| Steady Rest OD | 2″ to 30″ in diameter | |

| Rearchuck | Yes | |

| Work Envelopes (Min) | 6″ x 12″ 6″ x 14″ | |

| Work Envelopes (Max) | 19” x 120” 20” x 180” 32” x 224” 30” x 70” |

63″ x 98″ |

| Max Cutting Height | 63″ |

- Wire & Plunge

- Material hardness has little to no negative impact.

- Applicable to any material that is electrically conductive.

- A highly precise and reliable method

- No distortion on delicate sections or weak materials

- Very good surface finishes

| Type | Wire | Plunge |

|---|---|---|

| Max Tank Height | 16.5″ | 17.7″ |

| Working Envelope | 33” x 22” x 18” | 43″ x 32″ x 18″ |

| Open Height Min | 1.0″ | 1.0″ |

| Open Height Max | 16.5″ | 17.7″ |

MIC Group offers customized, innovative solutions that ensure exceptional quality and efficiency. Click the button below to download a summary of MIC Group’s services and capabilities.

Related Articles

5 Ways MIC Delivers Value Beyond Manufacturing

5 Ways MIC Delivers Value Beyond Manufacturing In today’s fast-paced world, businesses need more than

Advanced Machining and Assembly

These services are made to solve even the toughest manufacturing challenges that businesses face today.

Making the Complex Simple – MIC’s Expertise in Manufacturing Solutions

60 years of experience, MIC Group transforms manufacturing complexities into efficient solutions.

Request More Information

Learn more about the Engineering Design services offered by MIC