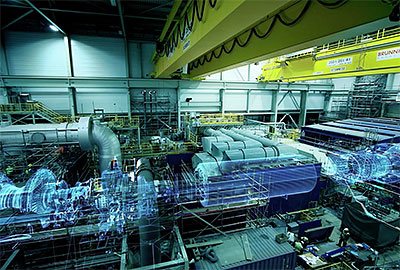

Power Generation

Turbine & Power Generation Manufacturing & Assembly

MIC Group delivers precision-engineered components for the power generation industry, utilizing advanced CNC milling, turning, and machining to meet the demands of high-performance turbines and energy systems. This sector requires components made from high-value materials, designed for harsh environments and extreme operating conditions. To support these complex needs, we have developed robust engineering, design, and quality management processes, ensuring exceptional precision, reliability, and compliance.

Beyond our in-house engineering and quality assurance capabilities, MIC Group partners with customers to manage outsourced services to exact specifications, ensuring seamless production and superior performance. With decades of industry expertise, we help customers navigate industry challenges by delivering cost-effective, high-quality manufacturing solutions for power generation applications.

Precision Components for Turbines & Power Generation:

- Gas Turbine Components & Assemblies – High-performance parts for efficiency and durability.

- Rotors & Shafts – Precision-machined for optimal functionality.

- Motor Components & Assemblies – Engineered for power and reliability.

- Compressor Components & Assemblies – Supporting high-efficiency energy systems.

- Impellers & Covers – Precision-crafted for superior fluid dynamics.

- Flywheel Housings – Designed for strength and performance.

- Fuel Cells – Built for advanced energy applications.

- Wind Turbine Blades – High-precision components for renewable energy.

With decades of experience, MIC Group remains a trusted partner for power generation manufacturers, offering innovative solutions, expert engineering, and seamless supply chain integration to drive efficiency, reliability, and long-term success.

Request More Information

Fill out the form below to learn more about the services offered by MIC for the power generation industry